L&T Group Websites

- Corporate

- Corporate – Arabic

- CarbonLite Solutions

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Precision Engineering and Systems

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

Regenerative Air Pre-Heater

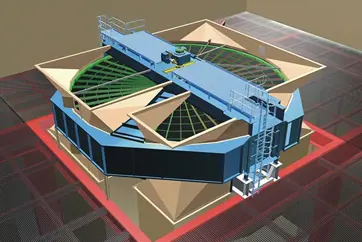

All Products- Pictures

The Regenerative Heat Exchanger is the most efficient and compact type of Heat Exchanger in use throughout the world. As a comparison, a tubular recuperative heater would weigh over four times the weight over a regenerative type with a corresponding in requirement in space layout. The other major advantages of a regenerator are clean ability and ease of replacement of Elements. This makes the Regenerative Heater most suitable for Air Preheat Application.

Types

- Bi-Sector Type - with Single Gas and Air Stream

- Tri-Sector Type- with Single Gas Stream but two air streams (Primary Air Stream and Secondary Air Stream)

- Quad-Sector Type- with Single Gas Stream - One Primary Air Stream sandwiched between two Secondary Air Streams for Leakage reduction.

Heat Transfer Process

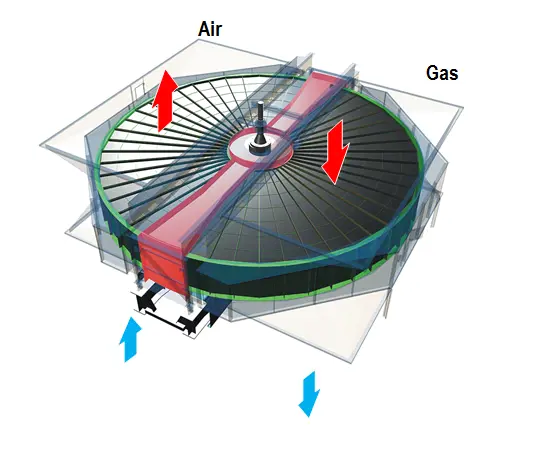

The heater absorbs waste heat from the flue gas as it leaves the economizer and transfers this energy to the rotating steel heat transfer element plates. The hot elements then rotate into the inlet air side which are used to provide the oxygen to fire the fuel in the boiler furnace. This heats the air, improving the efficiency of the boiler plant as energy is transferred back to the furnace, thus saving fuel. A further benefit is that hot air promotes stable combustion conditions. In the case of a mill heater the heated Primary Air is used to dry and transport the fuel to the furnace.

The L&T Howden Advantage

Howden Air Preheaters are optimized for performance and reliability, they are custom designed to suit the application, fuel and system design. Their contribution in Boiler Efficiency is up to 15% for only around 2% of boiler unit investment.

L&T Howden has a state-of-the-art facility at Hazira for manufacturing Air Pre-heater Components.